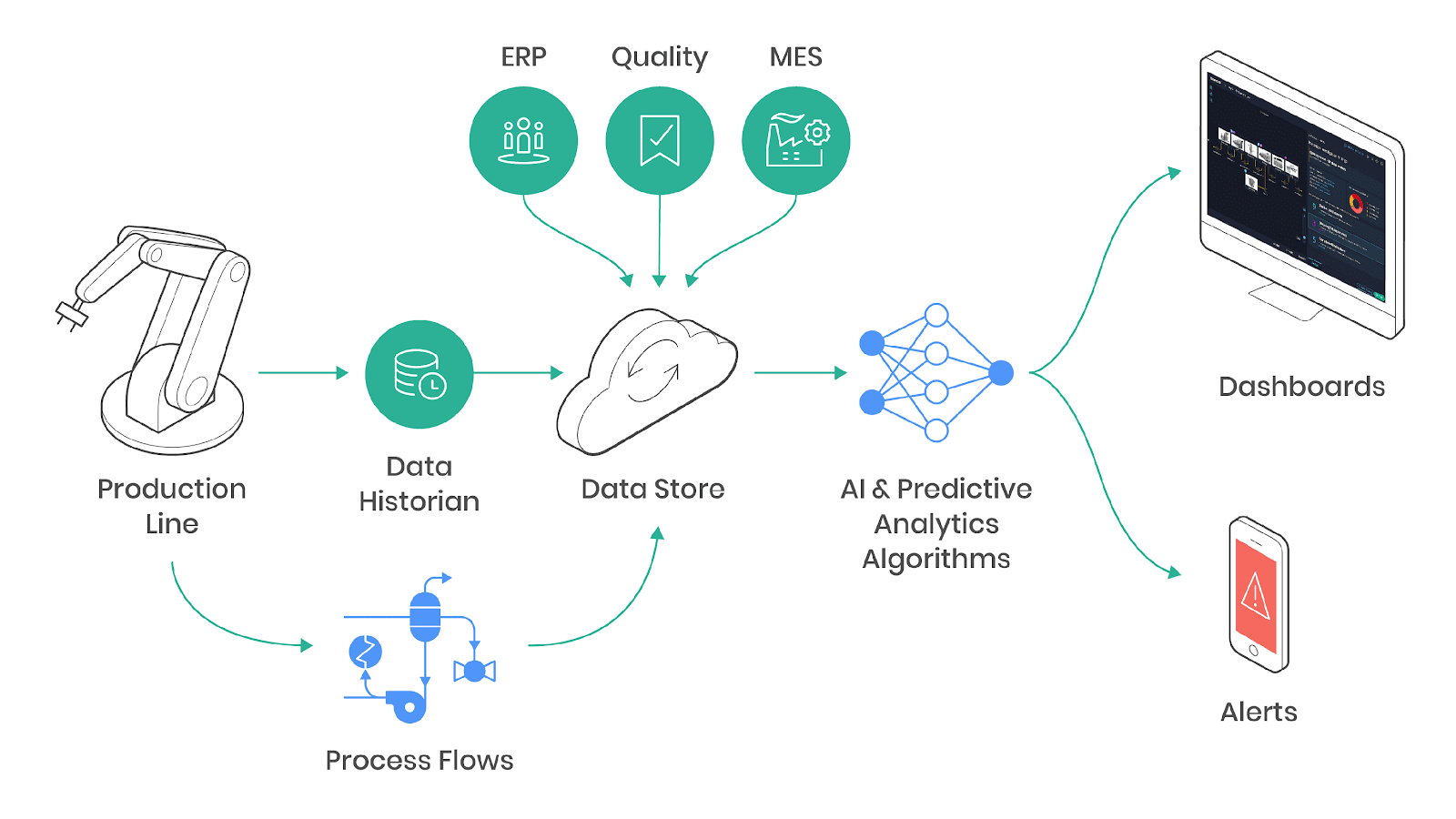

AI Revolutionizes Predictive Maintenance for Industrial AssetsAI Revolutionizes Predictive Maintenance for Industrial Assets The advent of artificial intelligence (AI) has transformed various industries, including manufacturing. One significant impact is the revolutionizing of predictive maintenance for industrial assets. Predictive maintenance involves using data analysis to monitor and predict potential failures in equipment and assets. This enables proactive maintenance, preventing costly breakdowns and maximizing uptime. How AI Empowers Predictive Maintenance: * Advanced Data Analysis: AI algorithms can analyze vast amounts of data from sensors, equipment logs, and historical maintenance records. They uncover hidden patterns and anomalies that indicate impending failures. * Accurate Predictions: AI models can make highly accurate predictions about the probability and timing of failures. This allows maintenance teams to prioritize tasks and plan accordingly. * Real-Time Monitoring: AI-powered systems continuously monitor assets in real-time. They detect changes in operating conditions, vibrations, or temperature, providing early warning of potential issues. * Prescriptive Maintenance: AI algorithms can not only predict failures but also recommend optimal maintenance actions. This helps optimize maintenance strategies and minimize downtime. * Automated Alerting: AI systems can automatically generate alerts when certain thresholds are exceeded, notifying maintenance teams of potential problems. Benefits of AI-Driven Predictive Maintenance: * Reduced Downtime: Proactive maintenance prevents unexpected breakdowns, minimizing asset downtime and maximizing production efficiency. * Lower Maintenance Costs: By identifying potential failures early on, maintenance teams can perform cost-effective repairs rather than costly overhauls. * Increased Equipment Lifespan: AI-driven predictive maintenance helps extend the lifespan of assets by identifying and addressing potential issues before they become severe. * Improved Asset Management: AI systems provide comprehensive information about the health of assets, enabling better inventory management and improved decision-making. * Enhanced Safety: By predicting and preventing failures, AI-powered predictive maintenance reduces the risk of accidents and ensures workplace safety. Conclusion: AI is revolutionizing predictive maintenance for industrial assets, enabling proactive maintenance practices that minimize downtime, reduce costs, and enhance equipment performance. Its advanced data analysis, accurate predictions, real-time monitoring, and prescriptive maintenance capabilities empower maintenance teams to optimize asset management and maximize production efficiency. As AI continues to evolve, its impact on predictive maintenance will only grow, further transforming the manufacturing industry.

Posted inNews